Plasma cutting

We use high-definition plasma cutting for steel plate up to 60 mm in thickness. Our seven state-of-the-art cutting machines are available in varying sizes, the largest of which offers cutting capacity up to 42 meters long and 5 meters wide. All of our machines are equipped with multiple high-definition plasma torches and oxyfuel cutting torches – for optimal production and shorter lead times. Our world-leading steel cutting facilities are also equipped with CNC cutting.

Plasma cutting for modern industrial applications

High-definition plasma offers a smoother and neater cut at much faster speeds, meaning the heat impact on your steel part is reduced. A smaller heat affected zone will limit any natural alteration of the steel’s properties which usually occurs in the processing phase. The superior cutting characteristics make high-definition plasma cutting the most effective, and often preferred, way to cut today’s industrial steel parts. At Proplate, we apply high-definition plasma, for example, in the manufacturing of crane lifting straps.

Bevel cutting for superior weld preparation

We also offer bevel cutting, used to prepare parts for the welding and assembly stage of production. We apply Y or K joints up to 40 mm thick. In doing so, we can deliver application-ready parts directly to our customers.

Efficient and sustainable production system

Our capacity for size and precision, allows us to offer maximum utilization of steel plate. Our large cutting tables allow us to, while cutting one plate, preparing the machine with the next plate.

Contact me for more information

ELME spreders – custom solutions for extreme stresses

Since early 1974, Swedish ELME has become the world leader in manufacturing shipping container spreaders. The secret is not just the company’s unique ability to customize its products, but also its collaboration with partners like Proplate, which can deliver...

Metso – Knowing and understanding each other makes all the difference

Metso is Proplate’s oldest customer. The two companies have collaborated since the founding of Proplate Oxelösund in 1999. “Naturally, this enduring relationship is extremely important. We know each other’s processes inside out and develop solutions together. It...

News

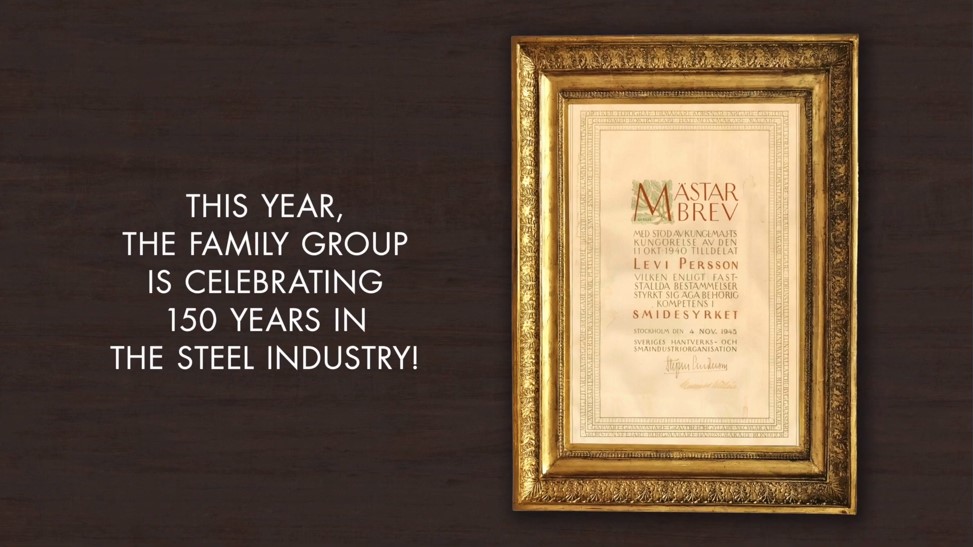

150 years in the steel business

From anvil to automation. This year, the family group that Proplate is a part of, celebrates 150 years. It all started in 1869, when forge master Per Andersson took his master craftsman’s certificate.