What we do

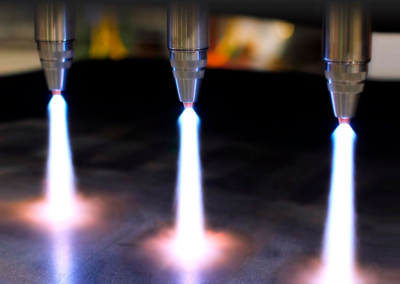

High quality manufacturing

We are specialists in the manufacturing of components and assemblies from steel plate made to exacting tolerances

Turnkey service

Our in-house cutting, machining, welding, painting and logistics teams offer a complete service from drawing board to delivery

Integrated Production

We offer a flexible production process that can be synchronised with your own, including IT integration, and full traceability

OUR WORK

WIND POWER

Proplate offers a complete, flexible, cost-effective and proven solution for anchoring wind turbine towers.

CONSTRUCTION MACHINES

Quality of each construction machine component is decisive in maximising the service life.

LIFTING INDUSTRY

Proplate straps are world-leading products in the crane industry. The straps link the counterweights and the trusses and comprise an extremely important component.

LOGISTICS AND MATERIALS MANAGEMENT

Moving, storing and handling bulky materials demands expertise and a specialist machine line-up.

MINING INDUSTRY

The mining industry is found throughout the world and is conducted in challenging environments. This requires durable wear parts.

INFRASTRUCTURE

Proplate is an expert in the manufacture of long and heavy items. With its long cutting tables and multi-function processing machines.

DEFENSE INDUSTRY

We provide products in penetration-resistant steel used extensively across defense & security industries

Our Facility

Production site

Our production facilitity is strategically located just south of Stockholm. We are neighbours with both SSAB:s steel mill and the Port of Oxelösund.

Capacity

High capacity in ultramodern machinery enables us to produce large volumes.

We have machinery with cutting tables up to 42 x 5 meters.

Sustainable Operations

Our sustainability mission is driven by a commitment to offer our customers long-term financially & environmentally responsible partnerships.

NEWS

Proplate has invested in one of Europe’s largest bed milling machines

This advanced REMA CNC machine enables the machining of components up to 17,000 mm in length with 4-axis capabilities, allowing for the processing of welded components.

Welcome Annelie Thörn – new HR Manager

“Joining the Proplate team is a great opportunity. Proplate stands out in the industry not only for its manufacturing expertise but also for its deep commitment to employee well-being.”

New gate for heavy transport

Recognizing the growing demand for more efficient logistics, this new gate couldn’t have come at a better time.

Our Clients