Processes

To remain competitive in the market, we believe that manufacturers must maximize value within the supply chain. At Proplate, we’ll help you rise to the challenge. Our multi-process capabilities, high-capacity and close proximity to SSAB’s steel mill mean that we can offer value unmatched by any other competitor.

Our world-leading production facilities combine several high-capacity supply processes to offer you reduced cost, shorter lead times and assured quality. We work to your long-term forecasts and make it easier for you to plan your production. From cut to machining, and weld to paint, we deliver customized industrial steel parts, ready for application across your production chain.

CNC-machining

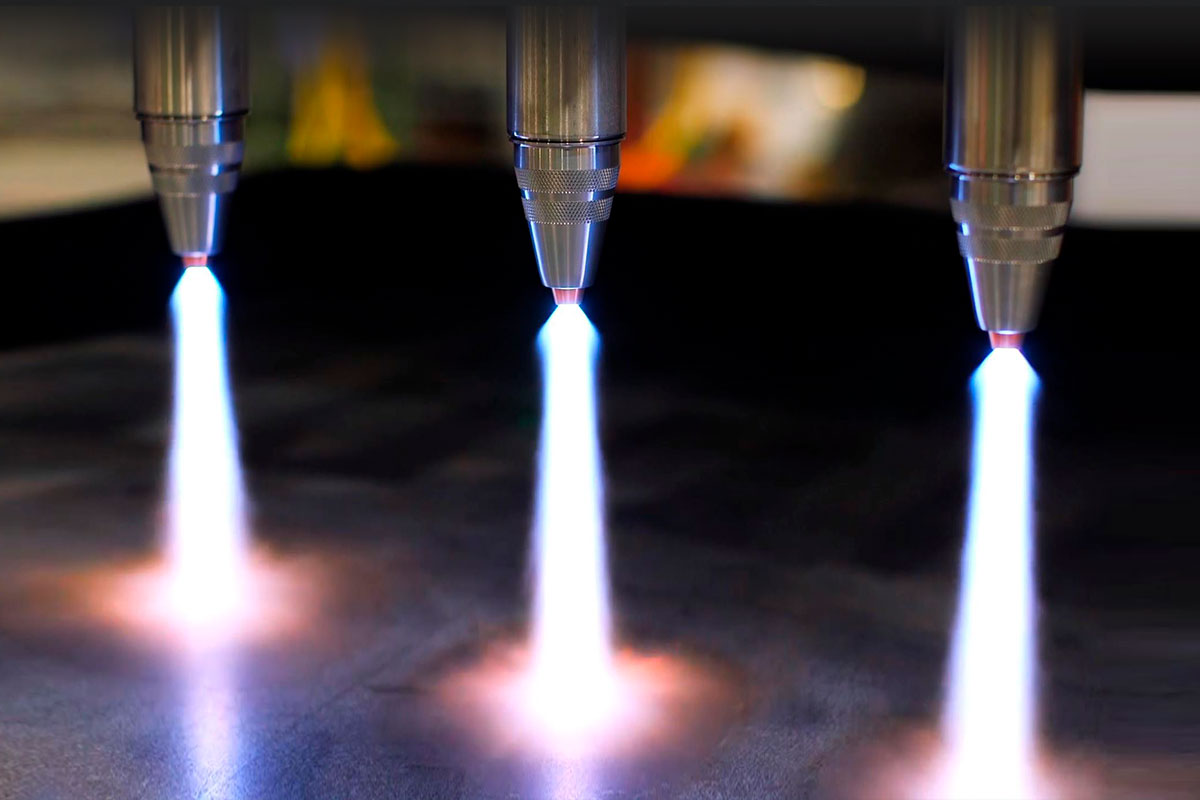

For high-capacity milling and drilling where precision counts.