Steel assemblies

Proplate´s steel assembly services are a natural part of our aim for constantly improved customer value. We make sure your steel parts fit perfectly into every aspect of your production chain. The result? Shorter lead times, lower costs, and a much smoother delivery of application-ready components to your site.

No matter the challenges – Proplate takes your production to the next level

We use welding and manual assembly of steel components wherever possible, from tension bars to anchor cages, to facilitate your own production. By letting us take care of your assembly process, you get several benefits:

- Only one partner instead of several assembly subcontractors

- Save time and costs

- Choose between different delivery configurations

High-capacity welding and manual assembly of steel components

We offer manual assembly and welding of your steel components, including both manual and automated/robotic welding. With us, you get several benefits, such as:

- a wide range of procedures including MIG-welding, MAG-welding and robotic welding.

- application of flame straightening afterwards for a perfect finish for your steel part.

- bevel cutting in our cutting machines for a superior welding preparation.

We are certified according to EN 1090-1 and ISO 3834-2

Proplate is welding certified according to the highest industry demands of EN 1090-1 and ISO 3834-2. Our pre-assembled solutions simplify your production and save on costly worksite expenses. Instead of assembling your industrial parts in your own facilities or at a subcontractor, or even on-site in the case of anchor cages, we’ll assemble it for you before delivery. In some cases, this can reduce your own production or construction time by many days. We offer this so you can best utilize your resources across other parts of your production.

Powerful welding robots for high-volume production of assemblies

Proplate´s robot welding equipment is made up of IGM Welding robots RTe with a Fronius TPSi 500 power source. The welding robot department has two different setups to match different customer needs:

- A heavy welding robot station with 10m long X-axis for long products as well as two manipulators.

- A system for high volume production of relatively flat parts (less than 300mm high). The robot welds plate segments and has a built-in press for pre-straightening to optimize the flatness of the parts.

59 000 m2 facilities for easy fitting together of any steel parts

At our 59,000 m2 facilities, we offer the space, tools and capabilities for easy fitting together of any parts. For example, we pre-assemble as many as half of the crane lifting straps we deliver to our customers. For wind turbine manufacturers, we supply anchor solutions in either a flat-assembly-pack or pre-assembled in sections.

As part of our service, we work directly with other sub-contractors to facilitate delivery of all required parts. This essentially means that we take responsibility to order any additional parts necessary for the assembly of your product – and assemble everything in our facilities. Thus, you get shorter lead times, save expenses, and receive a finished part straight into your production chain.

In other words – we’ll take care of production, letting you take care of your business. Do not hesitate to contact us!

Contact me for more information

ELME spreders – custom solutions for extreme stresses

Since early 1974, Swedish ELME has become the world leader in manufacturing shipping container spreaders. The secret is not just the company’s unique ability to customize its products, but also its collaboration with partners like Proplate, which can deliver...

Metso – Knowing and understanding each other makes all the difference

Metso is Proplate’s oldest customer. The two companies have collaborated since the founding of Proplate Oxelösund in 1999. “Naturally, this enduring relationship is extremely important. We know each other’s processes inside out and develop solutions together. It...

News

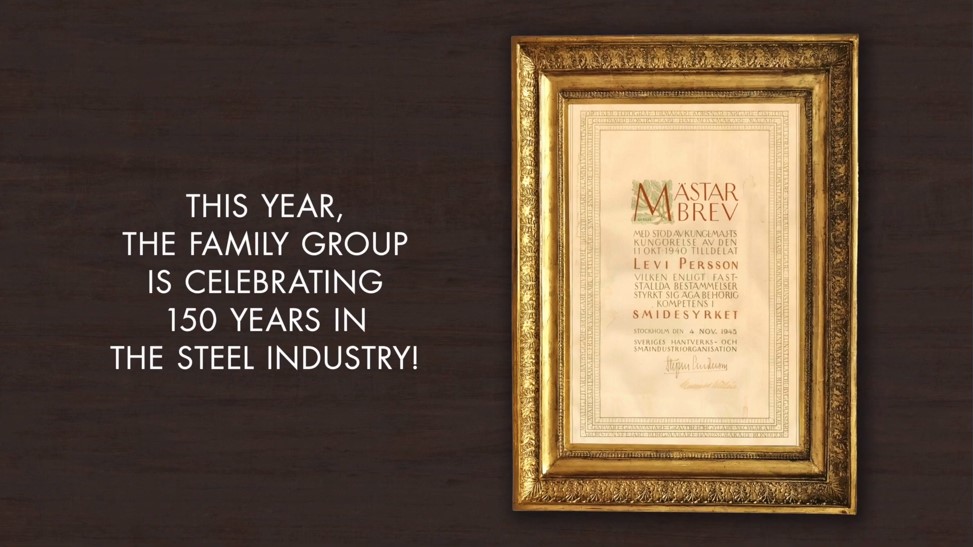

150 years in the steel business

From anvil to automation. This year, the family group that Proplate is a part of, celebrates 150 years. It all started in 1869, when forge master Per Andersson took his master craftsman’s certificate.