Surface treatment

Proplate offers high-quality priming and coating of your steel parts and assemblies in-house. Our facilities are equipped with three painting and drying booths which offer treatment solutions for large metal surfaces.

On-site spray painting of industrial steel parts

Steel parts which are transported to painting contractors can be exposed to low temperatures. This often requires a period of readjustment upon arrival, adding unnecessary delay to the customer’s lead time. At Proplate, we chose to invest in on-site facilities for painting, and metalizing – to enable application-ready delivery and cut your lead times.

To ensure a high-quality finish, we paint, coat and metalize our steel parts manually, using the latest technology from Wagner. We use both water-borne and solvent-borne products applied through high- and low-pressure pumps and airless, airmix and electrostatic technologies.

All of our painting booths have in-built floor exhaust outlets to provide effective filtering for the best possible finish of your steel parts and a good working environment.

Naturally, all residue paint and solvents are recovered to ensure an eco-friendly and sustainable operation.

Painting services of industrial steel components

Our painting booths are equipped to paint industrial components up to 20 meters in length and 7 meters in width.

Zinc surface treatment

In our efforts to always offer our customers more, we provide thermal zinc spraying to add corrosion-protection. This is used on exposed industrial parts, such as the outer flange on wind turbine anchor cages.

Contact me for more information

LIEBHERR – With a common goal: The customer in focus

Proplate supplies all the straps used in Liebherr-Werk Nenzing cranes. The crawler cranes, manufactured in the Austrian state of Vorarlberg, are used worldwide in industries that require safe lifting, such as wind power and construction. The straps are critical...

News

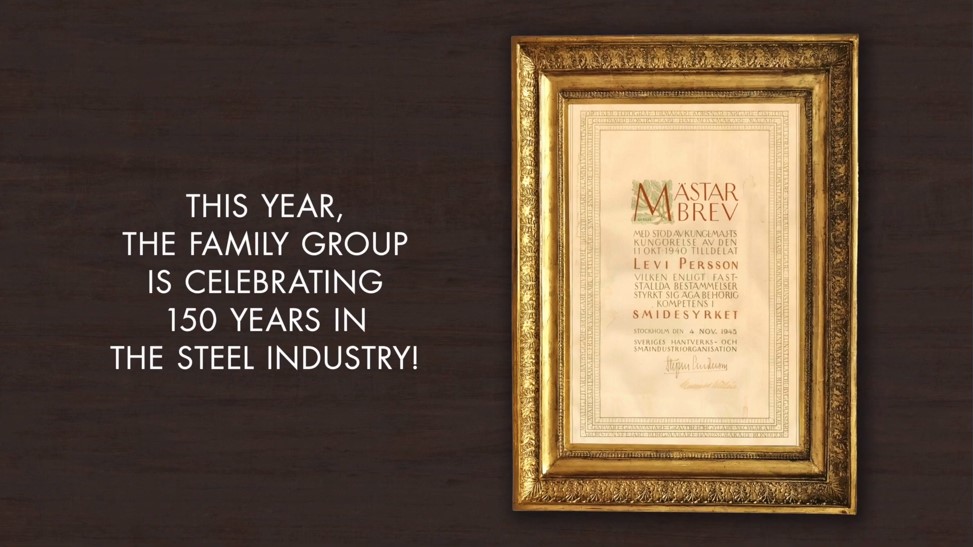

150 years in the steel business

From anvil to automation. This year, the family group that Proplate is a part of, celebrates 150 years. It all started in 1869, when forge master Per Andersson took his master craftsman’s certificate.